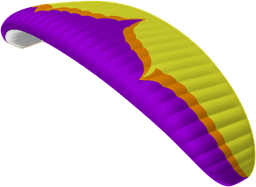

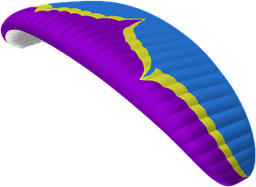

Product Info

The XXLite 2 is a single-surface ultra-lightweight mountain wing designed for serious Hike & Fly pilots and alpinists. This all-new wing delivers significantly improved performance and handling with a higher trim speed and easier landing, compared to its predecessor.

LEGACY

The first of its kind in 2012, the XXLite was one of the most unique and innovative paragliders to ever be put into production. The XXLite series still offers the lightest aircraft in existence when combined with the OZONE F*Lite.

NEXT GENERATION TECHNOLOGY

The XXLite 2 features a unique full span leading edge ram-air inflated tube. This provides a solid leading edge, which accepts lower angles of attack, yielding a higher trim speed and further acceleration. Now comparable with a dual-surface wing, the new speed range widens the safe flyable window and improves performance in real conditions.

LAUNCH & LANDING

The inflation characteristics are still ridiculously easy. The wing feels light and easy to raise overhead – even without touching the risers. The take-off speed is low, allowing you to leave the ground with just a few steps. Most significantly, the landing is vastly improved. The new flare performance allows soft, controlled landings, even in zero wind conditions.

IN ACTIVE AIR

Far more comfortable and confidence-inspiring than the original, it absorbs turbulence in a more controlled manner. The XXLite 2 offers excellent passive safety and is designed for pilots of intermediate ability. It exhibits docile behaviour in test maneuvers. Read about its EN certification here.

Available in sizes 16m and 18m and weighing in at just 1.3 kg (16m size) with a minuscule packing volume, the XXLite 2 is the ultimate hike and fly wing.